公司簡介

华丰科技企业股份有限公司,自1986年设立以来,在变频氩弧焊接及切割设备领域积累了专业的研发技术和丰富的 生产经验。 2001年,与美商POWER ARC LLC公司合作在上海成立了第二家生产基地--宝诺阳电源科技(上海)有限公司。该公司全面推行POWER ARC LLC公司之先进管理营运机制,并一次性通过英国BSI认证机构ISO9001质量管理体系认证。公司坚持执行周密的质量系统,确保每一个出厂成品及组件高质量特性。

公司现有产品主要包含:

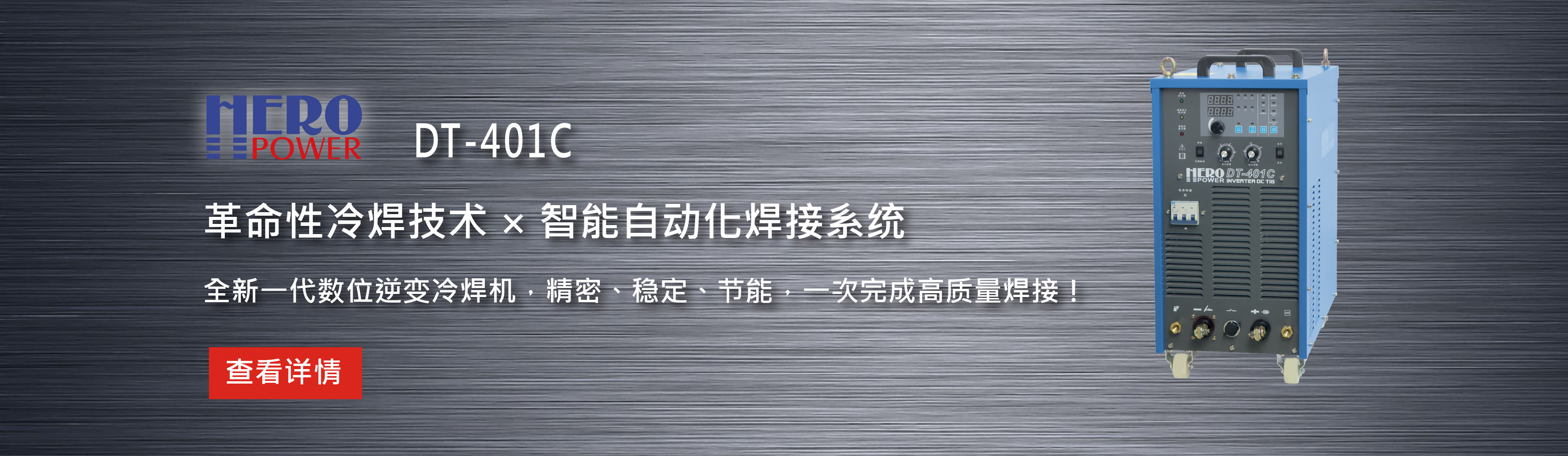

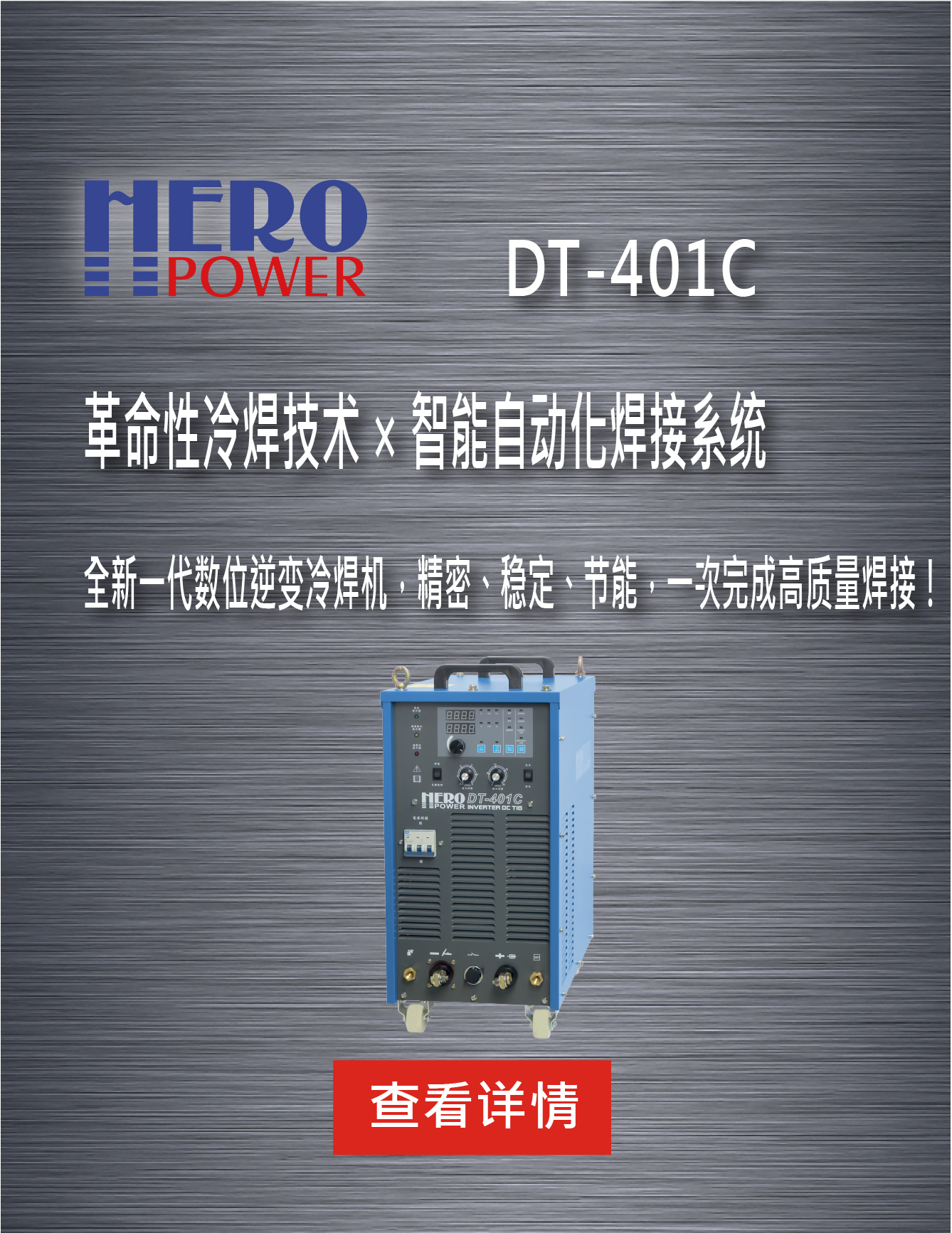

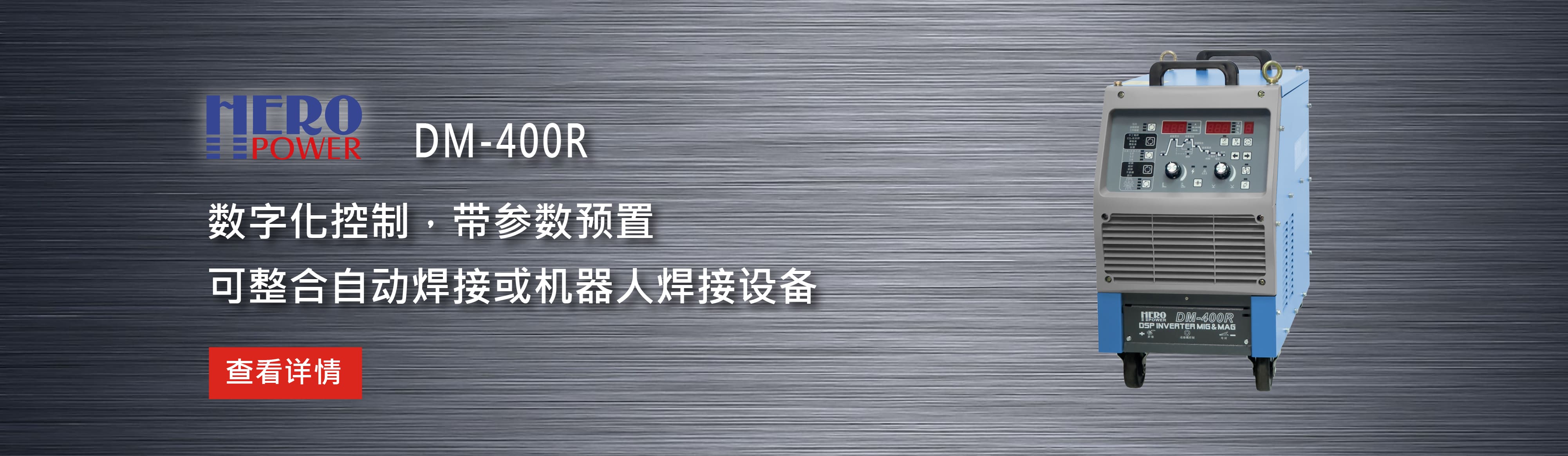

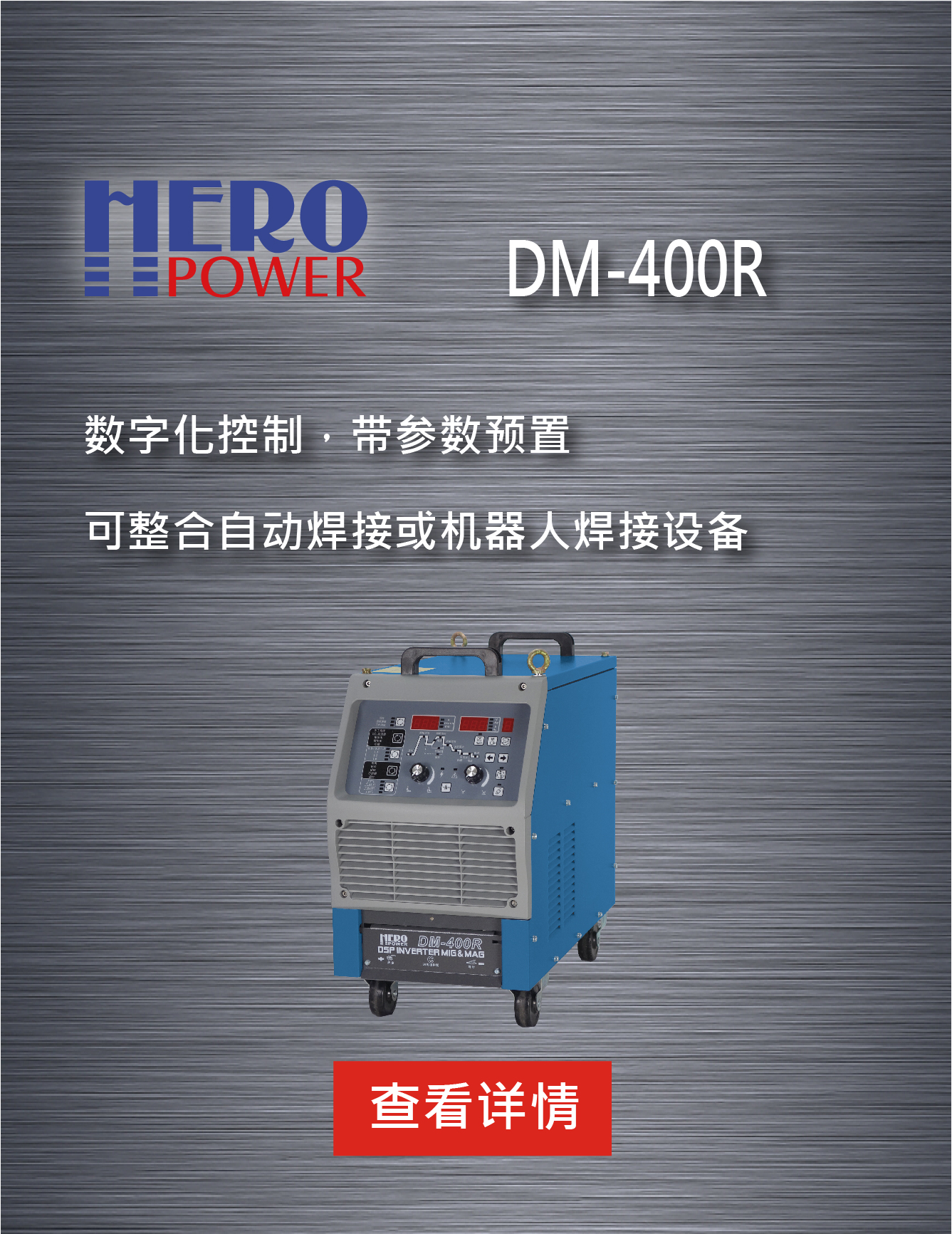

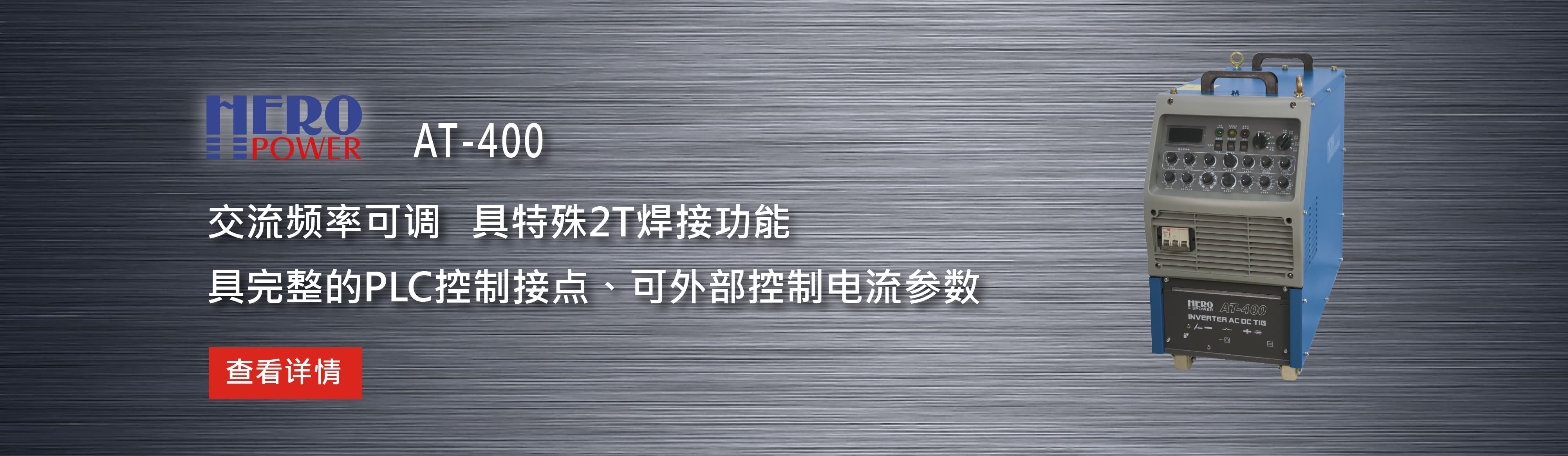

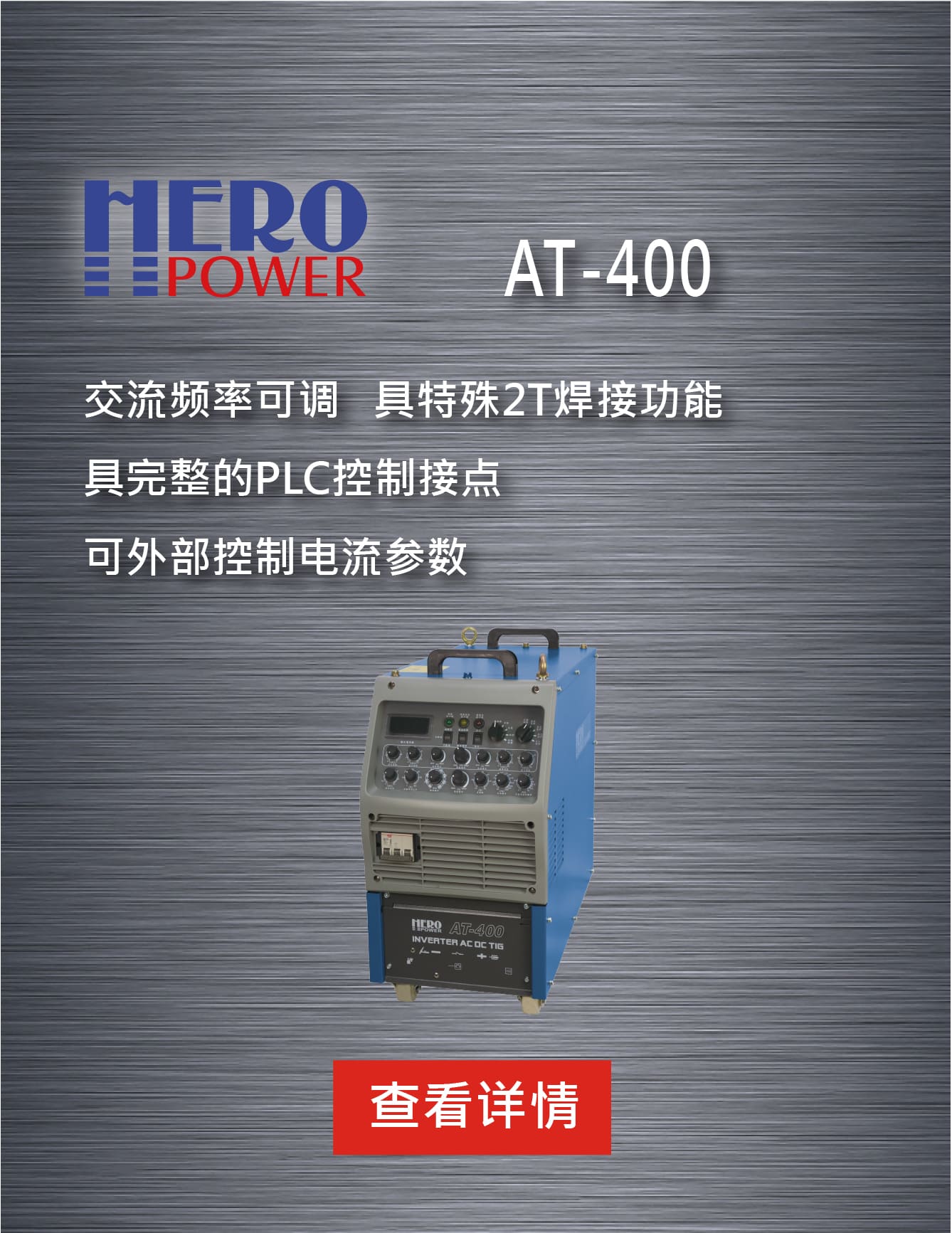

1.变频式氩弧焊机、变频式直流手工电焊机、变频式电离子切割机、CO2/MIG焊机。

2.闸流体CO2焊机、抽头式CO2焊接机。

企业宗旨:勤奋、服务、快乐 实现人生的真善美。

核心价值:诚信正直、长期耕耘、团队合作、价值创新!

质量政策:全员参与、追求卓越、持续精进、客户满意!

企业精神:热枕、效率、学习、创新、沟通。

经营理念:精益求精、止于至善!

最新

消息

台湾最顶尖焊机

华丰科技